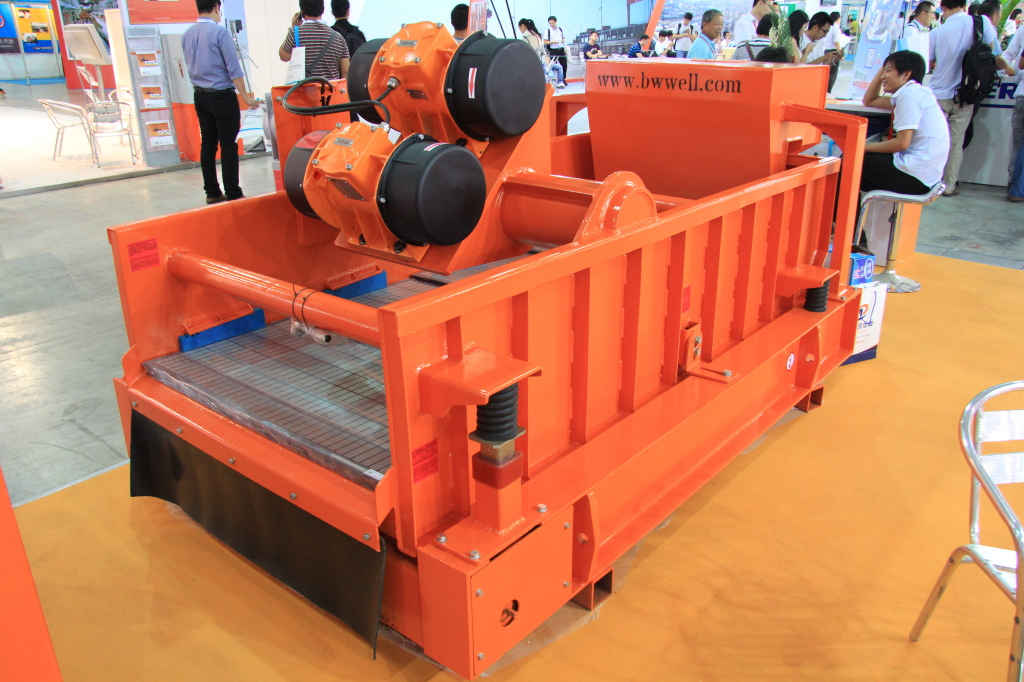

Linear shale shaker is used to select and classify the powdery and granular materials, which is widely used in plastic, abrasive, chemical, medicine, building material, food, carbon, fertilizer and other industries. The installation and maintenance of linear shale shaker are very important and should be paid much attention. Today, I will introduce the installation of linear shale shaker first.

First, before the installation, the operator should 1) check whether the motor sign is consistent with the specific requirements or not; 2) check whether the surface of the motor is damaged and deformed or not; 3) check whether the motor is fasted steadily or not; 4) check whether the power reservation is enough or not, and let it operate for five minutes with noload; 5) check the rotor is flexible or not, if it is abnormal, some measures should be taken; 6) measure the insulation resistance by 500V megger, and the stator winding should be done drying treatment no more than 120℃.

Then, in the process of installation, 1) the motor should be fastened steadily on the installation surface, and the surface must be insured to be smooth; 2) the motor could be installed horizontally; 3) adjust the vibration force; 4) the motor should has reliable groundlinking parts; 5) the motor wire should adopt rubber cable YZ500V with four cores, and the wire must be fastened with the vibrating parts and not be fold when connecting to the power.

Above are some processes or noticed tips about the installation of linear shale shaker. More information about the maintenance of linear shale shaker, please wait and refer to my next update.