Linear shale shaker is used in the first phase of solids control system, which deals with solids bigger than 76um. Of course, the screens of shale shakers play a very important role in the disposing process. Today, we will share some details about Brightway’s shaker screens.

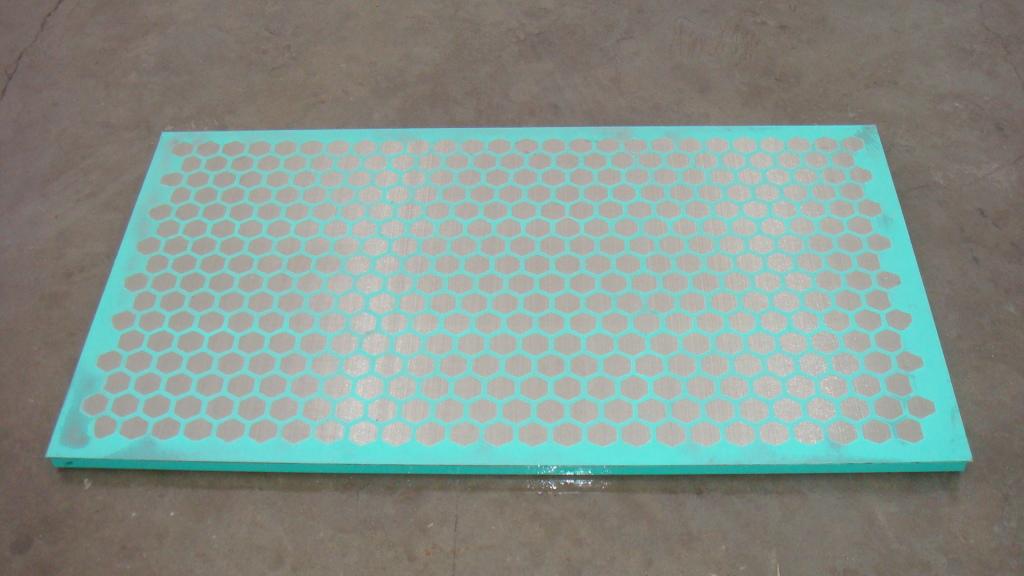

Brightway‘s M-Screen has 20-320 meshes, and its dimension is 585×1165mm. The frame of M-Screen is made of polyurethane, and the screen material chooses S.S304. This kind of screen of Brightway can be exchanged with the famous brand SWACO’s. It receives much populations from both the native land and foreign countries.

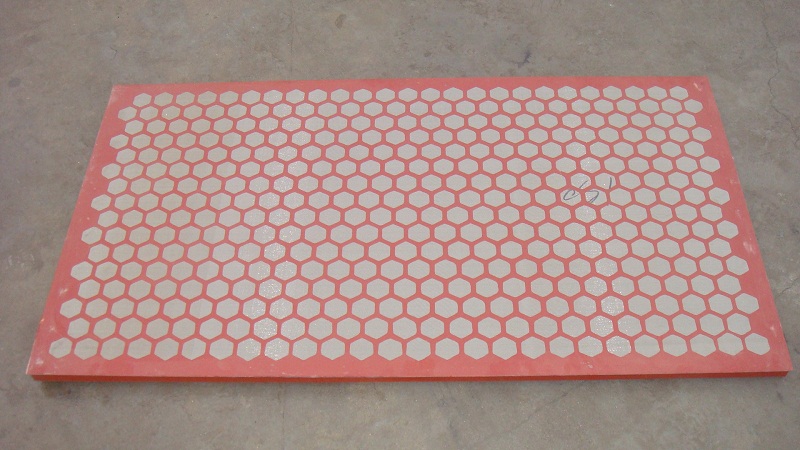

Brightway’s O-Screen has 20-320 meshes, and its dimension is 700/850×1250mm. The frame is made of carbon steel, and the screen material chooses S.S304.

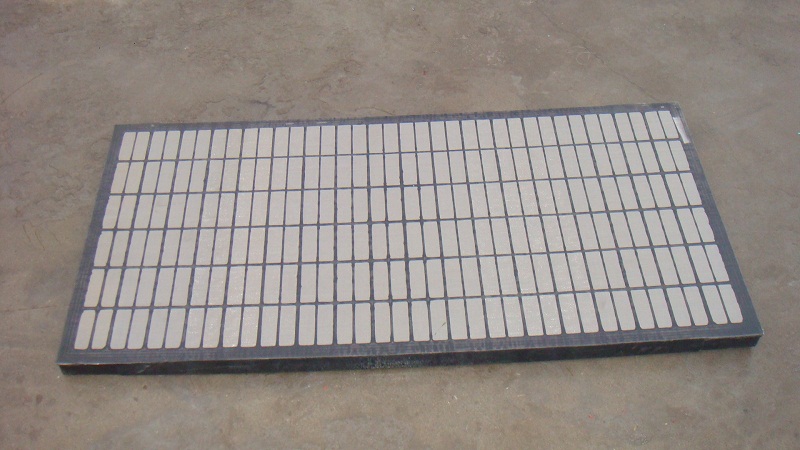

Brightway’s KT-Screen has 20-320 meshes, and its dimension is 635×1257mm. The frame is made of carbon steel, and the screen material chooses S.S304.

Brightway also has other kinds of screens, which are not displayed here one by one. And Brightway can also design and produce screens according to customers’ specific requirements. Screen belongs to the easily broken parts of shale shaker, some cause of premature screen failure for your reference. 1) Mishandling of screen panels during storage; 2) Improper handling during installation; 3) Improper installation of shaker screen to shaker basket; 4) Over/Under tensioning; 5) Dirty, worn or improperly installed deck rubbers; 6) Improper cleaning of the screens while in storage; 7) Extremely high mud weight; 8) Heavy solids loading; 9) Improperly manufactured screens; 10) Use of high pressure wash guns to clean or un-blind screens.