Drying shaker is a tool commonly used wellsite recovered liquid phase. Involved in drilling projects, take up to several oil and gas drilling, however, these are called industry “blood” of the liquid was prolific in the cold, or the Gobi desert, and these places have in common is the lack of water, but in fact it is a very water drilling project, so the drilling process how reasonable use of water, saving water, is a very worthy of consideration.

Drying shaker or dryer shale shaker, in the process of drilling waste is mainly for liquid recovery and primary shaker hydrocyclone excluded cuttings adsorption. This method of recovering the liquid phase in particular suitable for oil-based mud, mud can effectively reduce waste.

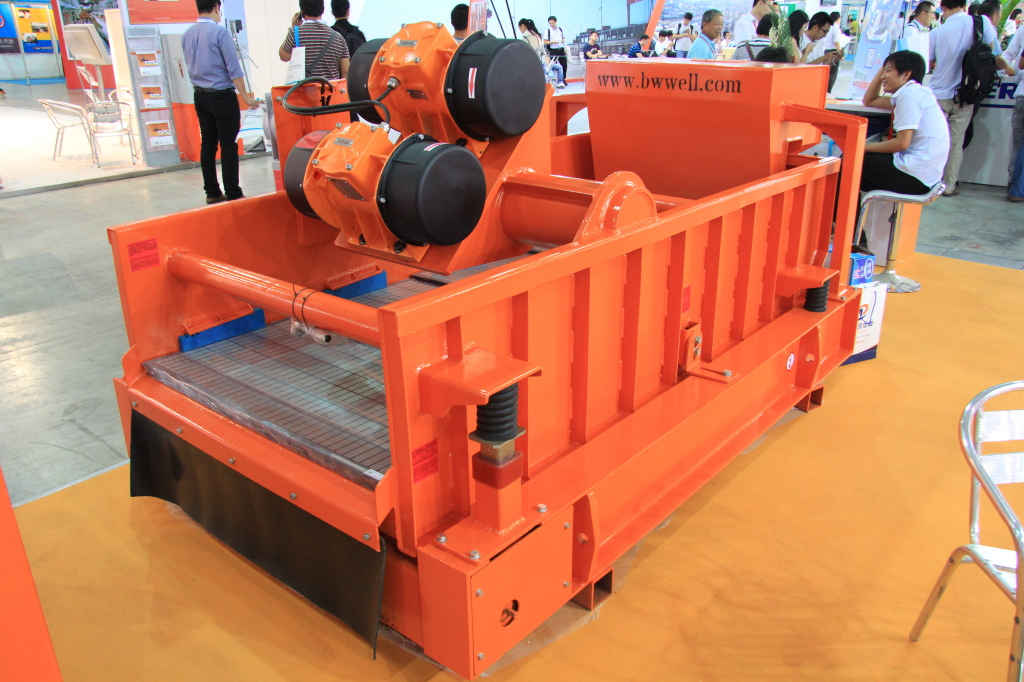

Relative to the main vibrating sieve, sieve dried using a finer screen cloth will be more, since the cuttings through the shaker screen is relatively dry, flowing through the screen is slow, with a strong vibration force can maximize the recovery of cuttings the liquid phase.

During use, the drying can be any device shaker solid control system, such as linear shaker, desander, in addition to mud, etc. used in combination. These devices combined treatment of the solid phase and then after exclusion of linear shaker screen cloth of a breakdown of liquid phase adsorption on a solid phase for recycling, all combined into drilling equipment cleaning system, with the main vibrating screen are aligned mounted drilling fluid tank. When not used as drying shaker, these devices can access the drilling fluid circulation system, facilitates fine particle separation. These drying shaker for the drilling fluid from the pump suction process desander and mud, and after drying process into the next level of processing equipment.